Materials Used in 3D Printing

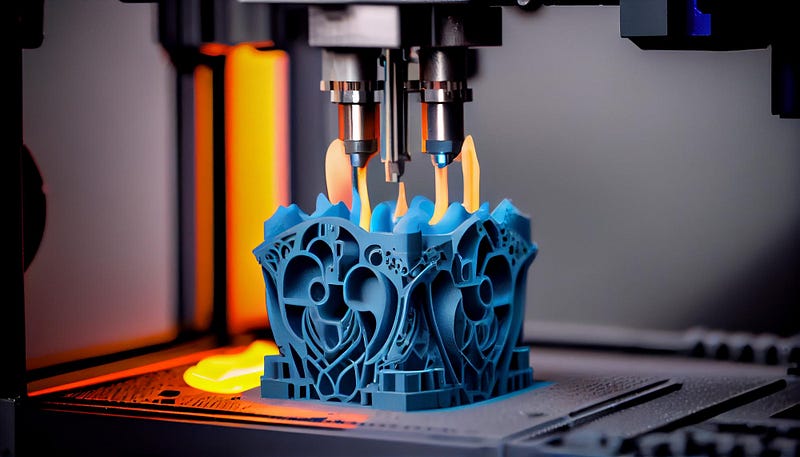

In the rapidly advancing world of 3D printing, the choice of materials plays a pivotal role in shaping the outcome of a project. Here, we delve into a diverse range of materials that fuel the 3D printing revolution, from common polymers to cutting-edge metal powders.

- PLA (Polylactic Acid): Widely recognized for its biodegradability and ease of use, PLA is a popular choice among 3D printing enthusiasts. Derived from renewable resources like cornstarch or sugarcane, PLA is eco-friendly and lends itself well to a variety of applications, from prototyping to decorative items.

- ABS (Acrylonitrile Butadiene Styrene): Known for its durability and impact resistance, ABS is a versatile thermoplastic used in a wide range of industries. Its ability to withstand high temperatures makes it a preferred choice for functional prototypes, automotive parts, and consumer goods.

- PETG (Polyethylene Terephthalate Glycol): Combining the best of both PLA and ABS, PETG offers excellent strength, flexibility, and chemical resistance. This makes it an ideal material for applications requiring durability and precision, such as mechanical parts and medical devices.

- Nylon: With its high tensile strength and flexibility, nylon is a powerhouse material in 3D printing. It finds applications in engineering-grade components, such as gears, bearings, and functional prototypes. Its low friction coefficient and resistance to wear make it indispensable in various industries.

- Metal Powders (e.g., Titanium, Aluminum, Stainless Steel): Metal 3D printing has revolutionized industries like aerospace, healthcare, and automotive. Utilizing powdered metals, this technique produces parts with exceptional strength-to-weight ratios, precision, and complex geometries. Titanium, aluminum, and stainless steel are just a few examples of the metals employed in this cutting-edge process.

- Resins (for SLA and DLP): Resin-based 3D printing technologies, like Stereolithography (SLA) and Digital Light Processing (DLP), use photopolymerizable liquid resins to create high-detail, smooth-surfaced objects. These resins range from standard to engineering-grade, catering to applications in jewelry, dentistry, and fine art.

- Ceramic Powders: 3D printing with ceramics opens up a realm of possibilities in industries like aerospace, electronics, and healthcare. By harnessing the power of ceramic powders, intricate and heat-resistant components can be manufactured, showcasing the adaptability of 3D printing technology.

3D Printing in India is experiencing rapid evolution. The demand for 3D printing services in Madurai is on the rise, driven by a growing interest in rapid prototyping, customized products, and industrial applications. As the technology continues to advance, the array of materials available for 3D printing will only expand, opening up new frontiers in innovation and manufacturing.

Comments

Post a Comment